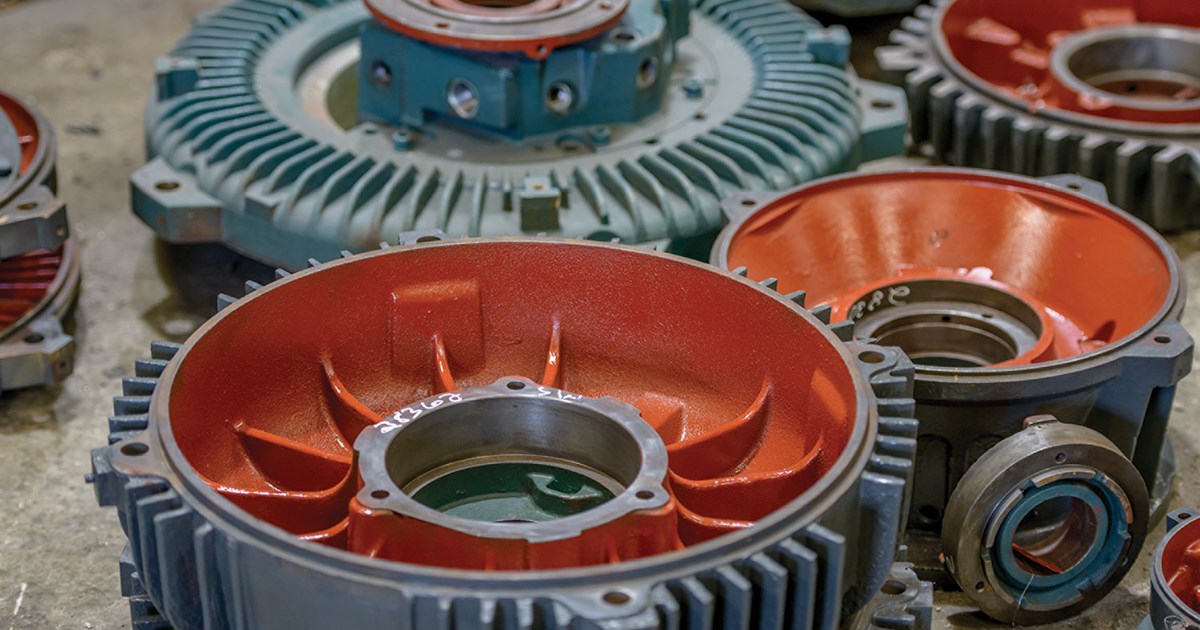

In the humid, salty air of the southern coastlines, industrial equipment faces a variety of challenges. Motors are vulnerable to corrosion and deterioration when exposed to harsh marine environments. At Red Stick Armature Works, we recognize the critical need for robust protection against these elements. That's why we offer Marine Coat Epoxy Paint from multiple brands as an essential option for our coastline companies. In this blog post, we'll explore why this specialized coating is vital for motor longevity and performance in the South.

1. Corrosion Resistance:

Saltwater is notorious for its corrosive effects on metal surfaces. Without adequate protection, motors operating in coastal areas are prone to rust and corrosion. This can compromise their integrity and lead to costly repairs. Marine Coat Epoxy Paint forms a barrier that shields motors from salt spray, moisture, and other corrosive elements, ensuring long-term sustainability and minimizing repair cost.

2. Enhanced Durability:

The harsh conditions of coastal environments require exceptional durability from industrial coatings. Marine Coat Epoxy Paint is specifically formulated to withstand the rigors of marine exposure, including UV radiation, temperature fluctuations, and abrasion. Its robust components provide superior resistance to degradation, prolonging the lifespan of motors and reducing the need for premature replacement.

3. Improved Performance:

Corrosion and deterioration not only affect the structural integrity of motors but also impact their operational efficiency and reliability. By applying Marine Coat Epoxy Paint, companies can maintain optimal motor performance even in the harshest coastal environments. The smooth, non-porous surface of the coating reduces heat buildup, and energy loss, resulting in smoother operation, longer MTBR, and lower energy costs.

4. Cost-Effective Protection:

While investing in corrosion protection may seem like an added expense, the long-term benefits far outweigh the initial costs. By proactively safeguarding motors with Marine Coat Epoxy Paint, companies can avoid costly repairs, replacements, and downtime associated with corrosion-related failures. Additionally, the extended lifespan and enhanced performance of protected motors contribute to significant savings over time, making it a wise investment for coastal businesses.

The process consists of 3 separate coatings:

1. The first layer is a two-component, high-build, multipurpose polyamide cured self-priming epoxy coating. The dry film thickness is 5-10 mils.

2. The second layer is a two-component, high solids epoxy coating. This is a semi-gloss coating with a dry film thickness of 4-8 mils.

3. The final coat is a two-component, gloss acrylic aliphatic urethane. This is a high gloss topcoat 2-3 mils thick that is weather resistant and has excellent color and gloss retention.

In the dynamic landscape of the southern coastlines, protecting industrial equipment against the corrosive forces of nature is paramount. Red Stick Armature Works is committed to providing comprehensive solutions to safeguard motors operating in these challenging environments. Our Marine Coat Epoxy Paint option offers unmatched corrosion resistance, durability, and performance, ensuring that your motors remain reliable and efficient for years to come. Don't let saltwater corrosion compromise your investment—choose Red Stick for superior protection and peace of mind.

For more information on how Marine Coat Epoxy Paint can benefit your coastal operations, contact Red Stick Armature Works today.